The need to make was still there however, and being a teenager "guns" featured heavily in what would be cool to make. The next idea was to start building a paintball gun turret. The idea was simple, big, but simple. We would make a seat section with 2 or more paintball guns attached. This would pivot between two uprights and these would sit on a base which would turn left and right. The frame would be welded from tube steel, and the drive would either come from geared dc electric motors or from a pneumatic actuator system. I say we as I am referring to myself and my friend Matt who helped me throughout the project.

We decided that the total cost would come to about £500 and we felt we could get this money together over the time of the build. So we set to work designing, and cutting and welding, visiting scrap yards for vehicle chairs, and purchasing pneumatic cylinders.

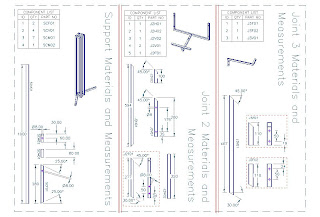

The progress was good at first and with the aid of the cad designs that I put togeather the frame came togeather.

It slowed as time went on due to school work and a relatively small amount of commitment at points. We pretty much stopped working on it in the run up to our a-levels and the project was left dormant for a long while. Finally, with interest from the London Paintball Centre, for prospective purchase of the turret we were spurred back into action. The school had offered me a job as a DT technician so I had access to the workshop at almost any hour. There were numerous set backs along the way and many parts had to be remade due to poor design by us and also due to the fact that many things were changed part way through such as the guns, the base support system, the drive system and the electronics setup.

If this project did nothing else, it taught me an awful lot. The project was finally taken of our hands three years after starting and costing just less than 3 times the original budget. This was the first large project that I have done and was what I see now as the practice for the car that I am about to start work (makeitdrive.blogspot.com)

More complex control systems using valves requiring automatic control based on an external input require an actuator. An actuator will stroke the valve depending on its input and set-up, allowing the valve to be positioned accurately, and allowing control over a variety of requirements.

ReplyDelete